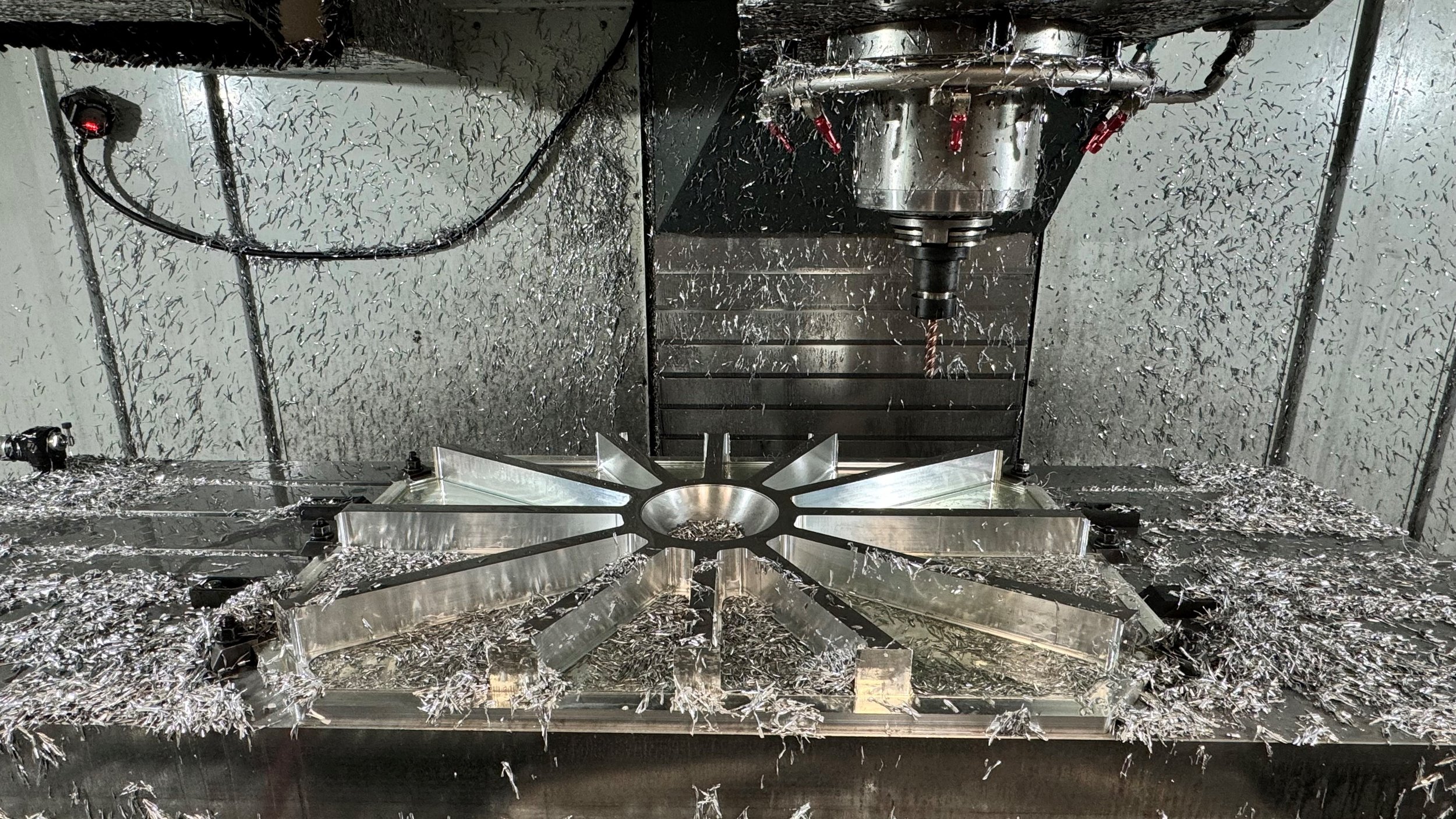

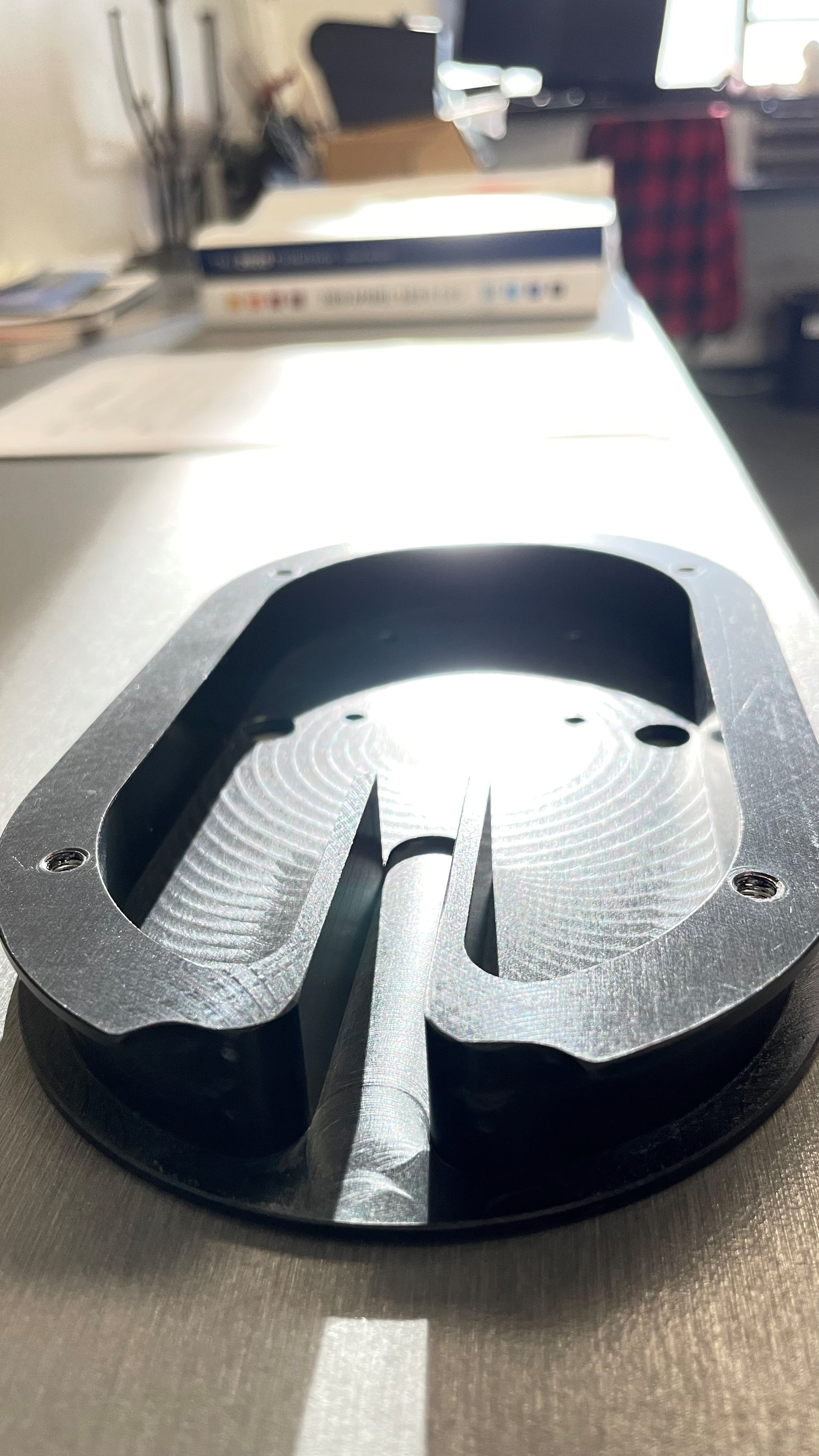

High Precision Machining

LaserForm’s precision machining department is the newest addition to our arsenal of operations offered. In 2013, we acquired a local machine shop and brought over all of its machinery and employees. Since its acquisition, we have replaced all of the machines with new, state of the art machining centers and increased its size by 30%. There is no question that our customers love the quality of our parts and the option of LaserForm being a “one stop shop” for all of their products. For further details regarding our equipment and abilities, see the drop down tabs to the right of this text.

-

With mid-level production capabilities our goal is to grow with the needs of our customers while maintaining high integrity customer service. To be a vendor you can trust to get the job done right, on time, and at a fair price. If we can’t do it, we’ll tell you, and if you want, we’ll help you find someone who can. It is our commitment to provide our customers with the highest quality workmanship, on-time delivery, and excellent customer service at reasonable shop rates.

-

HAAS VF4 SS:

Travel: X50’’/Y20’’/Z20’’

HAAS VF5:

Travel: X50”/Y26”/Z25”

HAAS VF6:

Travel: X64”/Y32”/Z30”

HAAS VF7:

Travel: X84’’/Y25’’/Z25’’

HAAS VF9:

Travel: X84”/Y40”/Z30”

-

Mazak Quickturn QT250MY:

Abilities: 12” x 36”

Live tooling

Bar feeder

Mazak QuickTurn QT200MY:

Abilities: 10” x 20”

Live tooling

Bar feeder

Mazak Nexus QT-350:

Abilities: 16.5’’ x 60’’

Enco Lathe

Abilities: 13’’ x 36’’

-

Clausing 3 head gang drill

Ceruti Horizontal w/3” spindle, vertical head attachment and D.R.O on all axis x48” Y 40” Z 30”

Marvel cnc cutoff saw

Ellis Dual Mitre Band Saw

Haas cnc rotary head