WaterJet Cutting:

Our waterjets utilize a 60,00 PSI stream of water and granite to erode a 0.030’’ line in the stock material. Laserform has experience cutting a wide range of materials such as: tool steel, titanium, mild steel, stainless steel, aluminum, copper, bronze, UHMW, foam, PVC and stone.

-

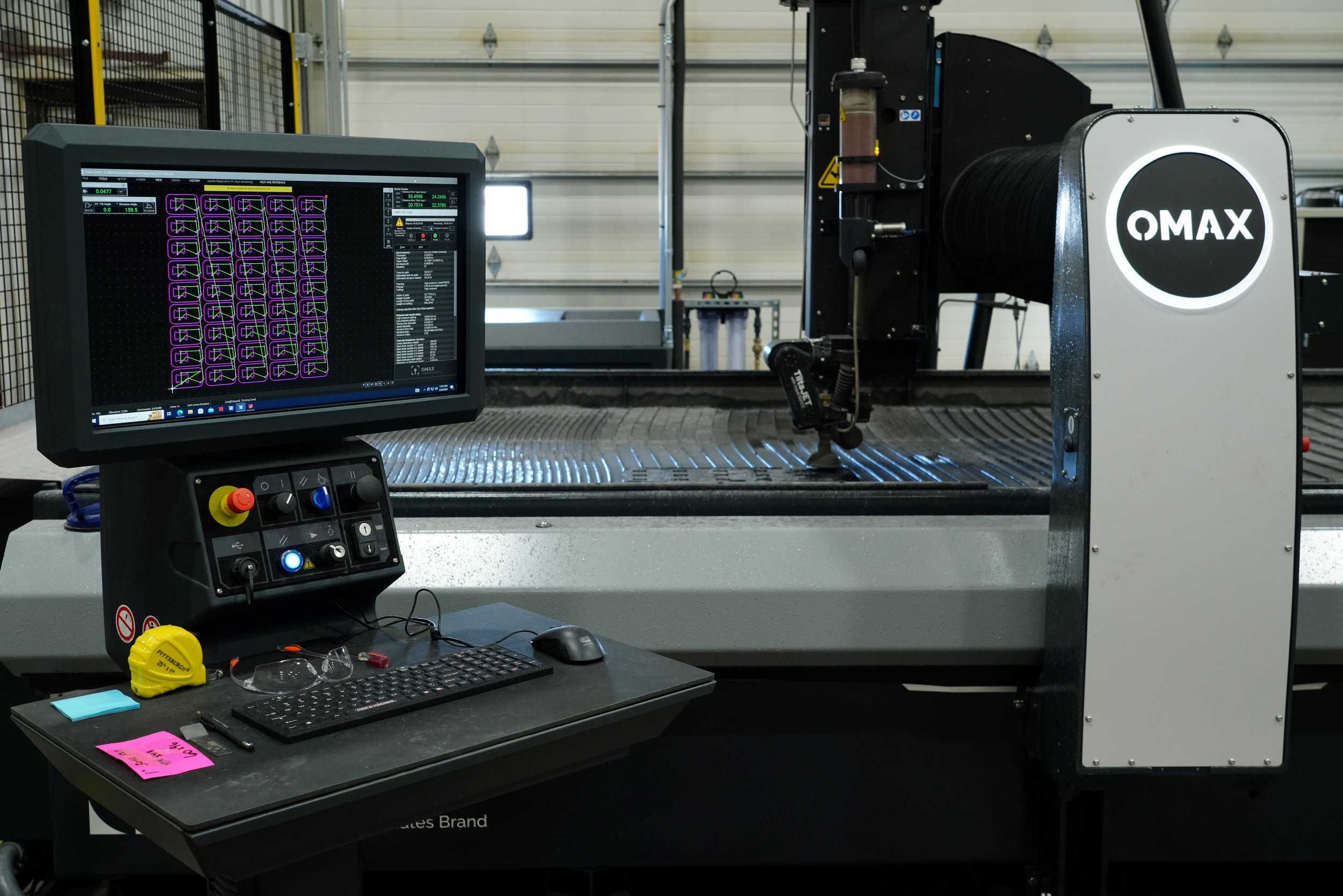

(1) Omax 120X JetMachining Center

Custom made table giving us one of the largest cutting envelopes in the country. (120’’x300’’)

Dual cutting heads on one carriage to maximize efficiency.

Tilt-a-jet head which allows us to compensate for stream deflection to maintain a perpendicular cut.

(1) OMAX 80x Abrasive WaterJet

80’’ x 160’’ cutting envelope

60,000 psi

Tilt-a-jet head

-

Process materials up to 8″ thick

High precision cutting to +/– 0.005″ tolerance

Cut envelope of 300” X 120”

Superior edge quality, with no heat affected zones

Produce almost no localized heating, permitting use with hazardous or heat-sensitive materials

Minimizes warping of material